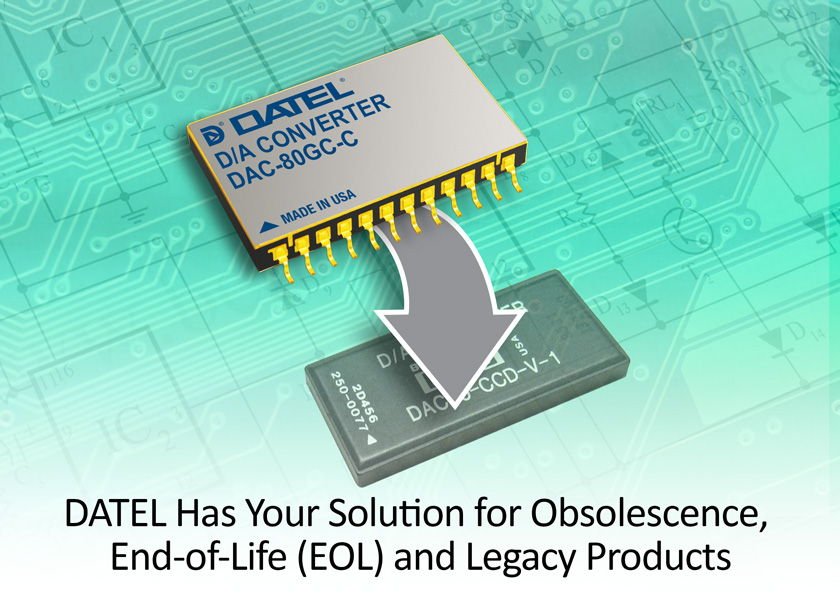

Replacing and Enhancing Competitor's Obsolete Microcircuits

Looking For a Solution to Procure a Unique or Obsolete Component? DATEL Specializes in Replacing and Enhancing Obsolete Microcircuits. As a premier designer and manufacturer of Data Acquisition Systems and components for over 40 years, DATEL is frequently approached by our customers to help them resolve obsolescence, End-of-Life (EOL) and/or reduced access to qualified legacy products. We are uniquely positioned to provide alternative solutions to on-going and mature defense and aerospace programs which suffer from Diminishing Supplier-Base issues.

Looking For a Solution to Procure a Unique or Obsolete Component? DATEL Specializes in Replacing and Enhancing Obsolete Microcircuits. As a premier designer and manufacturer of Data Acquisition Systems and components for over 40 years, DATEL is frequently approached by our customers to help them resolve obsolescence, End-of-Life (EOL) and/or reduced access to qualified legacy products. We are uniquely positioned to provide alternative solutions to on-going and mature defense and aerospace programs which suffer from Diminishing Supplier-Base issues.

DATEL has decades of design and manufacturing expertise in digital and analog products for the Commercial, Industrial, Medical and Military/Aerospace markets by offering:

- Standard, special or custom products

- Form-Fit-Function for obsolete products

- Low volume and high volume applications

- No obsolescence - DATEL products are guaranteed to be available for long-term programs

- Available RoHS and Non-RoHS versions of products/systems

- All commercial, industrial, medical and military grades of products are produced in our Mansfield-based MIL-PRF-38534 certified facility

- Hermetically sealed packaging

- In house environmental testing

DATEL Manufacturing Capabilities

Chip and Wire on Ceramic

Operating from our 180,000 square foot facility in Mansfield, Massachusetts, we have been producing Mil-certified Data Acquisition components since 1970. The hermetically sealed components are assembled in our class 100,000 clean room on thick-film substrates, and all Hi-Rel products are fully tested over their extended operating temperature range.

Operating from our 180,000 square foot facility in Mansfield, Massachusetts, we have been producing Mil-certified Data Acquisition components since 1970. The hermetically sealed components are assembled in our class 100,000 clean room on thick-film substrates, and all Hi-Rel products are fully tested over their extended operating temperature range.

- Full MIL-PRF-38534 Class H, ISO 9001:2008 certified and compliant facility

- Die attach process - conductive and non-conductive epoxies

- Wire Bonding - 1 mil Au wire

- Seam Seal - welded lid

- Conducted in a class 100,000 clean-room

- Hi-Reliability commercial, industrial and MIL-883 electronic components

- ROHS and non ROHS compliant processes are available

Chip-Wire and SMT on FR4

To provide the smallest packages at the lowest cost we have introduced a new form of Hybrid, incorporating chip-wire and SMT technology on FR4, housed in Mini SMT Quad-Pak or traditional TDIP.

To provide the smallest packages at the lowest cost we have introduced a new form of Hybrid, incorporating chip-wire and SMT technology on FR4, housed in Mini SMT Quad-Pak or traditional TDIP.

- Die attach with 1 mil Au wire bonding

- Mini SMT Liquid Crystal Polymer Quad-Pak

- Commercial and extended temperature range testing

- ROHS and non-ROHS compliant processes are available

Surface Mount Technology

Commercial products not requiring hermetically sealed packaging can be manufactured using SMT technology to provide the same performance but at a lower cost.

Commercial products not requiring hermetically sealed packaging can be manufactured using SMT technology to provide the same performance but at a lower cost.

- Auto pick and place

- Manual pick and place

- AOI inspection

- Lot control verification

- Auto pin insertion

- High-temp solder assembly

- Through-hole assembly

- Flying leads

- Encapsulation

- ROHS or non-ROHS compliant

Thick Film

Hermetically sealed products manufactured in our Class 100,000 clean room are assembled on thick-film substrates.

Hermetically sealed products manufactured in our Class 100,000 clean room are assembled on thick-film substrates.

- Conductor, dielectric, glassivation, resistor pastes

- Single- or multi-layer

- Thick film resistors screened onto the substrate

- RoHS and non-RoHS compliant

Test & Environmental

All products, whether using chip-wire, chip-wire and SMT, or solely SMT, are fully tested to their specified static and dynamic parameters. Hi-Rel devices are fully tested under their specified extended temperature ranges. An MES tracking system monitors each step of the manufacturing process and records all test results, providing lot control and traceability for all data acquisition products.

All products, whether using chip-wire, chip-wire and SMT, or solely SMT, are fully tested to their specified static and dynamic parameters. Hi-Rel devices are fully tested under their specified extended temperature ranges. An MES tracking system monitors each step of the manufacturing process and records all test results, providing lot control and traceability for all data acquisition products.

- Dynamic FFT & static ATE

- Extended temperature testing

- Burn-in

- Temp cycling

- Centrifuge

- PIND

- Hermeticity testing

- Life test

Facility Quality Standards

MIL-PRF-38534 Qualified

MIL-PRF-38534 Qualified - Quality Assurance Manual

- ISO-9001 Registered

- ISO 14001 certification

- MES tracking system

- Lot control and traceability on all Data Acquisition products

- Company-wide, continuous improvement programs